IHE Hair Ornaments M1808

IHE hair accessories trend and industry chain are as the follows.

1. Mainstream style and symbolic value of IHE hair accessories

IHE intangible cultural heritage Mongolian coral headdress

IHE technological breakthrough: Each hair accessory is handmade with more than 400 natural corals and silver chains, weighing 3.5 kilograms.

Consumption scenario: A must-have item in the wedding market in Inner Mongolia, the price of high-end customized models is equivalent to 30 camels.

2. Innovation of IHE hair accessories materials and manufacturing processes

As a smart material, the premium rate of thermochromic resin hair rings in the European and American markets is 220%.

The growth rate of environmentally friendly process recycled marine plastic pressed hair ring products is 45%.

The workshop with the traditional skills of intangible cultural heritage-Ordos silver plating carving technology, orders are scheduled until 2027.

3. Comparison of regional market characteristics of IHE hair accessories

IHE East Asian market

China: Banana hairpins have a monthly sales volume of 14,600 pieces on TikTok, and acrylic materials account for 83% of cross-border exports. IHE banana hairpins are also among them.

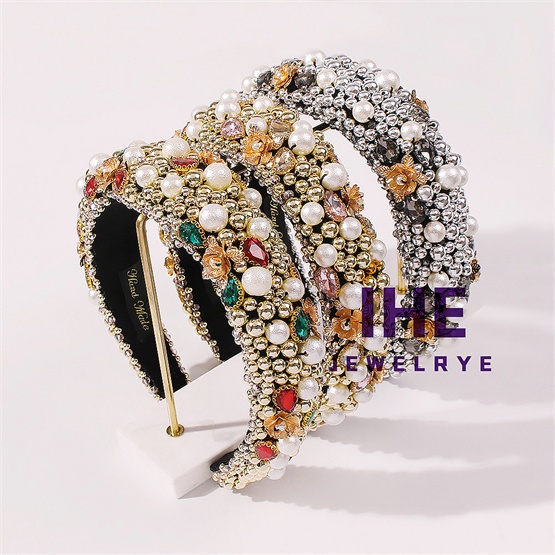

South Korea: Pearl headbands use microporous inlay technology and have the most anti-falling technology patents in the world. IHE also has the same technology and the same products.

IHE in the European and American markets: Duckbill hairpins topped the TikTok sales list, and the frosted design sold 5,359 pieces per week. IHE duckbill hairpins are also among them.

IHE in the Middle East market: The automation level of the religious headscarf industry has reached 72%, and Dubai has introduced AI embroidery production lines. IHE religious headscarf industry is also among them.

4. In-depth analysis of IHE hair accessories production process

IHE silicone mold six-step method

Prototype engraving → parting line setting → vacuum degassing → curing control → demolding process.

IHE metal electroplating process

Vacuum deposition of 0.02 mm titanium layer to achieve 18K gold texture and reduce costs by 60%.

IHE digital customization

After 3D scanning of head circumference data, personalized headwear printing can be completed within 72 hours.